Professional Thermal Flow Simulation Analysis

Kolink Int'l. Corp. has been deeply involved in the thermal management field for many years, equipped with top-tier thermal simulation analysis software such as FloTHERM XT, SOLIDWORKS, and Icepak, along with a professional team of thermal engineers. From the early stages of product development, including thermal simulation analysis and heat dissipation solution consultation, to the later stages of trial production and mass production, Kolink Int'l. Corp. is your strongest and most reliable partner.

We provide a comprehensive thermal management service, joining the product development process from the very beginning to assist in thermal design, ensuring an efficient and optimized solution for our customers.

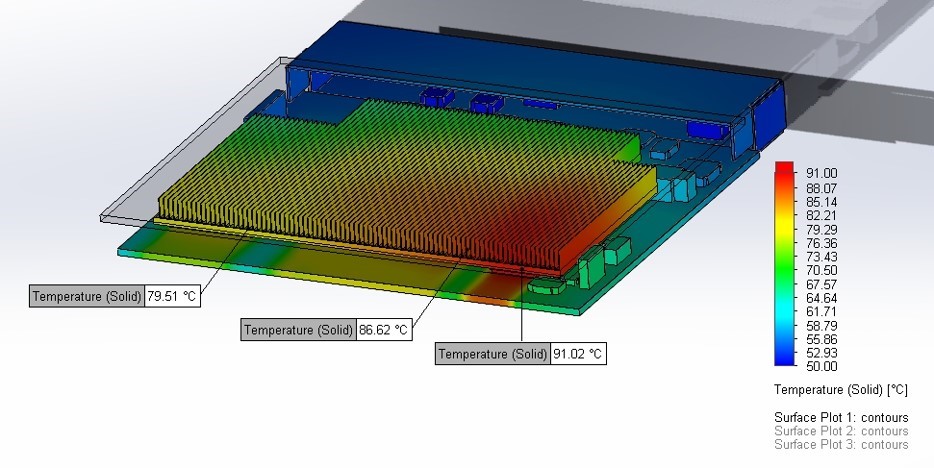

Kolink Int'l. Corp. uses the advanced FloTHERM XT thermal simulation software, which can be applied to thermal management simulations and planning in all product development stages. For any complex mechanical design environments, FloTHERM XT allows for detailed analysis. Combined with Kolink Int'l. Corp. professional thermal engineering team, we provide effective thermal solutions and define the necessary thermal specifications.

![]() Applied to Telecommunications(5G)

Applied to Telecommunications(5G)

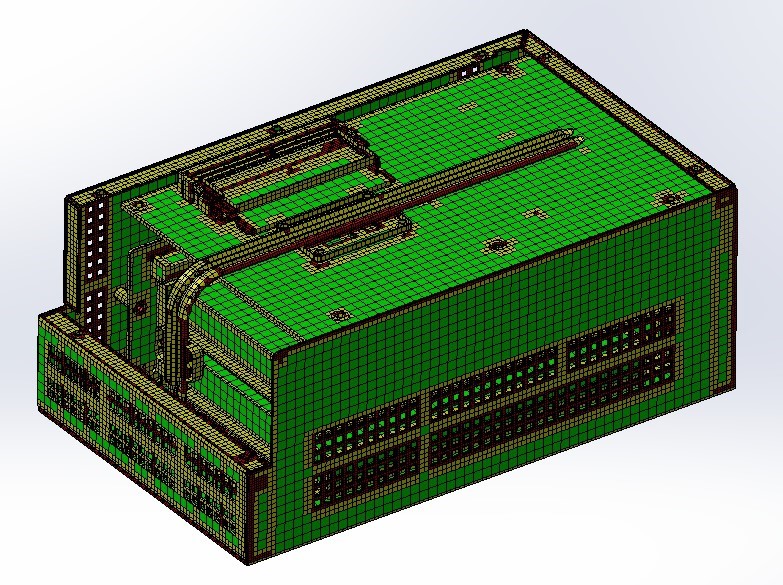

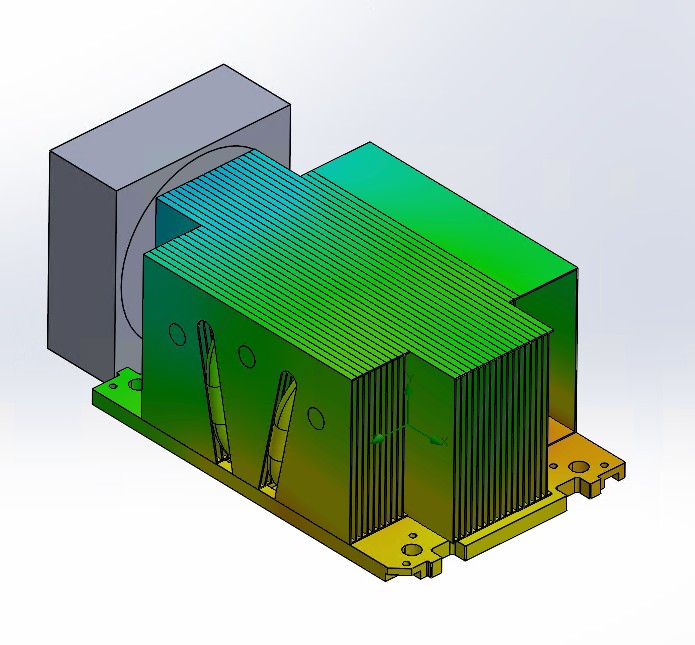

SOLIDWORKS provides a variety of simulation solutions, tools, and features to meet the needs of different industries and applications.

Kolink Int'l. Corp. uses various simulation software to cross-check design performance and identify differences, ensuring that each solution is optimized for the specific requirements of our customers. This approach allows us to fine-tune and enhance product designs to achieve the best possible thermal and structural performance.

![]() Application in Set-Top Boxes

Application in Set-Top Boxes

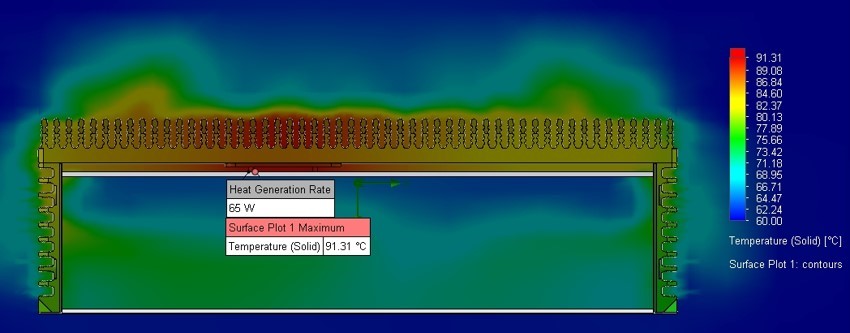

![]() Application in Network Cards

Application in Network Cards

![]() Application in Semiconductor IC Packaging and Testing

Application in Semiconductor IC Packaging and Testing

With built-in models for a wide range of electronic products, Kolink Int'l. Corp. can create accurate simulations based on the specific characteristics of the system, components, heat sinks, and packaging. By calculating the overall temperature field and flow distribution, we can identify potential thermal issues and provide recommendations for design improvements. This approach significantly shortens the design cycle and helps save costs, allowing for more efficient development of high-performance products.